Printed electronics

Development work since 2020

Printing electronic circuits with conventional letterpress processes, such as screen printing or inkjet printing, is particularly interesting where the lowest possible manufacturing costs are important, but resolution and precision may be low - i.e. at most microscopic, but not nanoscopic, as in high-performance electronics, for example in computer and smartphone chips. These are, for example, RFID tags, electronics for the internet-of-things, smart textiles - so-called wearable electronics, and cheap mass production of touch screens, LEDs and solar cells. There is also promise for use in hobby electronics and rapid prototyping.

Direct printed circuits are already an established market worth about $40 billion. Conductive inks account for 83% of total sales. Screen printing processes are mainly used, as they have lower viscosity and stability requirements than inkjet inks. Currently, only silver nanoparticles are used. Their mass proportion in the ink can be between 25 and 75%. The price for a litre of conductive screen printing ink is between $500 and $1500 per litre. For a marketable conductive inkjet ink, a price 2 to 3 times higher can be estimated. Source: Shlomo Magdassi The Chemistry of Inkjet Inks; ISBN-13 978-981-281-821-8.

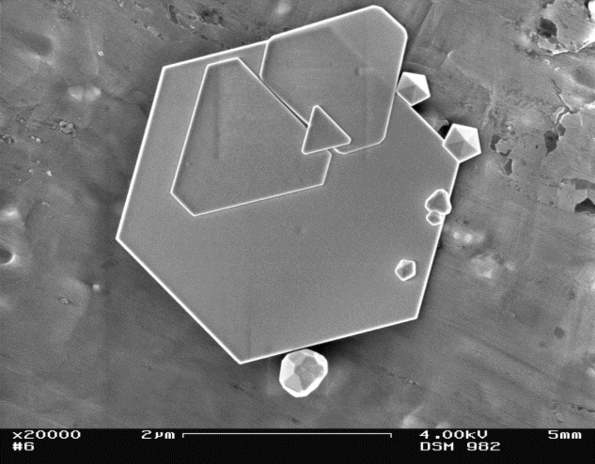

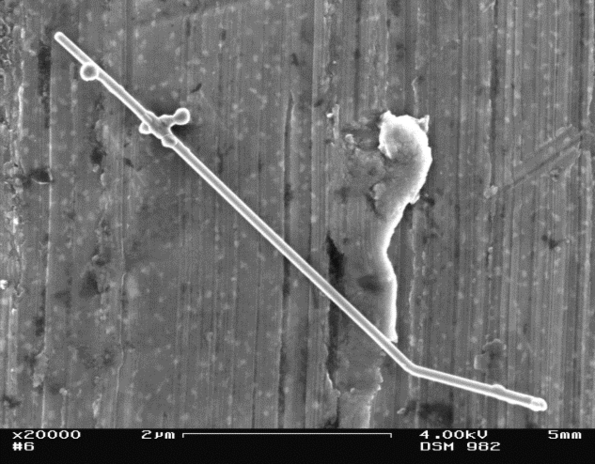

On the other hand, it is also possible, although more difficult, to synthesise metallic nanoparticles or microparticles with a high aspect ratio. Such particles have the shape of nanoscopically thin flat platelets or wires:

Such a form is much better suited for use as a conductive dispersion - one would achieve the same conductivities with smaller metal contents. This is because much of the metal in voluminous particles does not contribute to conduction. Rather, it is the contact surfaces that are important. And this inert portion would just be saved with flat particles, as they are practically all surface. This would make it possible to achieve the same conductivity with a solid content of 10% that is normally achieved with 60%. In the technical language of physics - particles expanded in one or two spatial directions have smaller percolation thresholds. This, of course, can be expected to result in a large saving in manufacturing costs.